We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Steel fabrication is part of our industrial bedrock due to its strength, heat resistance, durability, and ease with which steel fabricates.

It remains crucial in housing construction, bridge building, and making factories and other large structures ‒ foundational components of our society that will forever remain in high demand. Industries calling for steel fabrication are essential for the world to exist and function as we know it. And so is flame cutting ‒ one of the most important tools in structural steel fabrication today.

In this blog post, we will explore the importance of structural steel fabrication in various industries today and the advantages of flame cutting in achieving precise structural steel joinery and connections.

At Amber Steel, we specialize in laser, plasma and flame cutting, and have always been a "total source" service for the production of quality steel products. Quality is achieved by utilizing the right production technique for the right product. Our continual investment in equipment and technology enables us to offer clients many production alternatives to achieve exact product specifications and tolerances. If you’re interested in learning more about steel cutting or have a project in mind that you would need our expertise on, do not hesitate to reach out. We’re always one email or phone call away.

Steel fabrication is utilized most in architectural engineering and construction.

These industries are absolutely essential to a robust, thriving civilization. Unsurprisingly, given their importance, they’re also exceptionally challenging industries, placing strenuous expectations on those involved.

Complex, demanding designs and final products calling for enough durability and integrity to withstand all conditions and environments means strong materials are of the utmost necessity.

Various design methods and innovations have taken steel fabrication to the next level, including different manufacturing processes, such as cutting, grinding, blending, brazing, and welding. On that note, the primary topic of this blog will be flame cutting structural steel–but more on steel fabrication first.

Here’s a list of use cases where steel fabrication shines brightest:

Steel fabrication offers streamlined construction, reliable strength, and low weight for high-rise buildings.

It creates large spaces cost-efficiently, making it an ideal fit for industrial buildings.

Warehouses benefit from steel fabrication due to the reduced prices required to construct vaster spaces.

Light gauge steel construction is a technique that optimizes the making of residential buildings.

Steel fabrication meshes well with temporary structures since it lends itself to easy setup and removal processes.

Steel fabrication offers the following construction-based benefits:

Fabricating steel offers a structurally sound method that can be manufactured to strict tolerances and specifications.

Excess material can be 100% recycled and is energy efficient.

There are no concerns about steel warping, buckling, bending, or twisting, making it straightforward for modifications.

Price fluctuations are rare, providing optimal cost-efficiency. You know what you’ll be paying, and it’s affordable.

It improves construction quality while reducing the required maintenance.

Steel fabrication’s environmental and social benefits are worth further shedding light on. The durability of steel and its reusability can’t be understated. More to the point, continued recycling won’t affect its most beneficial characteristics.

Combining steel fabrication with other enhancements will also vastly enhance the energy efficiency of a building.

Processes and materials of great importance – the crucial, foundational elements of industry, society, and our economy – can’t have discernable weaknesses. We can’t afford our businesses, homes, and infrastructures to contain structural discrepancies.

Thus, steel fabrication must be executed optimally. It must provide the robust, sturdy backbone we’ve come to rely upon and be sustainable and cost-efficient. Fine-tuned processes are of the topmost priority. Too much is on the line for anything less than the best materials.

One such approach is flame cutting fabrication. We’ll describe this process below and analyze its role in precise joinery and connections.

Generally speaking, flame cutting is a preferred solution throughout the equipment construction process. It’s also relied upon by machine shops far and wide.

This cutting method combines propane and oxygen, producing a controlled flame on carbon steel plating.

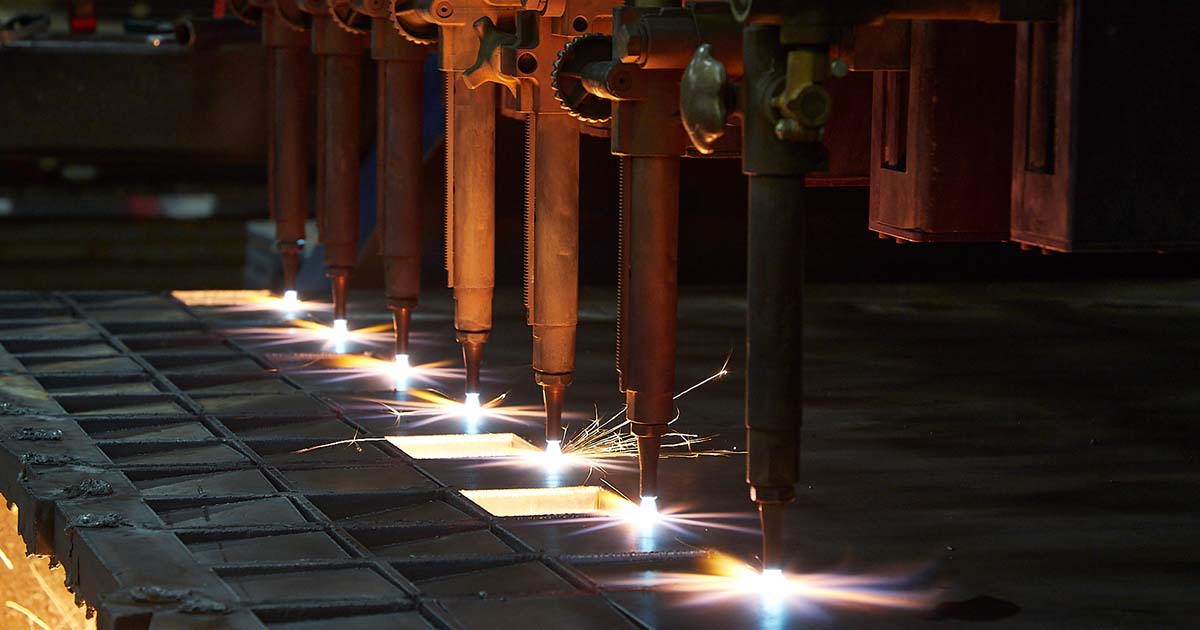

flame cutting is used interchangeably with the term “oxy-fuel cutting.” It shapes and separates steel components. Outer rings of torch-nozzle jets pre-heat the steel’s surface. Meanwhile, a central jet directs another oxygen stream to the targeted cutting area.

Rapid steel oxidation occurs, removing materials due to the gas-related pressure.

Mechanized methods are used for steel cutting, which involves the torch being mounted on a machine. Manual approaches are also still applied by many in the industry, entailing an operator to hold and guide the torch.

flame cutting makes it possible to cut complex shapes. Also, computer technology can be integrated into cutting machines to offset material waste. In some instances, multi-cutting head machines are applied for high-volume production.

Amber Steel possesses two Oxy-Fuel machines, each boasting up to eight burning stations, offering efficiency and streamlining speed. This makes us the ideal choice for flame cutting fabrication for anything between one-offs to thousands of profiles.

Below is a list of advantages reaped from flame cutting fabrication:

Flame cutting structural steel can’t be matched in the realms of precision, specifically regarding thick steel. Flame cutting can precisely cut through steel materials of up to 270mm. That’s unprecedented and unparalleled.

Projects calling for exact dimensions and intricate designs benefit tremendously from this precision.

Thick steel maintains its integrity when flame cut and ensures each cut adheres to–and even exceeds–rigorous quality standards.

Flame cutting and cost-efficiency go hand in hand, no more evident than with thick steel in large volumes.

Material wastage and operational costs are vastly reduced due to flame cutting fabrication and its ability to handle vast quantities and extensive sheets.

With flame cutting, you’ll stay within your budgetary constraints while optimizing production.

With flame cutting fabrication, thick steel is cut fast without sacrificing quality–a stark difference from other methods.

Flame cutting is ideal for projects with demanding deadlines, helping keep companies on time despite any possible scheduling challenges.

Any company aiming to diversify its offerings or approaches has a valuable tool in flame cutting.

Flame cutting will deftly yield complex–or straightforward–shapes, its applications ranging from precision engineering (e.g., shipbuilding and aerospace) to heavy construction.

A high-quality surface is a trademark of flame cutting, typically yielding a smooth finish that suits almost all applications.

Flame cutting thicker steel might lead to surface imperfections, but further treatments can seamlessly remedy these.

Flame cutting industry advancements in technology have garnered more environmentally friendly machinery and approaches.

Modern flame cutting fabrication increases energy efficiency, reduces emissions, and has established a reputation for sustainability in steel processing.

Flame cutting technology continues to advance and grow more capable in how efficiently it cuts through thick steel. Computer-controlled cutting systems improve speed and precision.

Such advancements enable tighter tolerances and more nuanced designs, making flame cutting an increasingly better fit for complicated applications.

When flame cutting fabrication is involved, there can be flexibility and customization in design. Simple and complex geometrical shapes can be easily formed, meeting project requirements, no matter how unique.

Highly customized projects stand to benefit significantly from flame cutting fabrication.

Flame cutting gets the job done with a vast range of steels, from carbon to mild and mild alloy.

Thus, flame cutting is suitable for many projects and a diverse option for many forms of steel fabrication.

A highly skilled workforce and flame cutting fabrication go hand in hand. Flame-cutters have vast expertise, ensuring the utmost precision and care goes into each job, ensuring top-tier outcomes.

Joinery has a crucial role in assembling different components together in a structurally sound and visually pleasing fashion. It’s an essential part of executing top-tier work.

Through joinery, you clear out clutter, simplify the aesthetics of an interior design, and benefit from seamless two-material transitions.

It’s all about robustness and sturdiness, ensuring an exceptional finished product that stands the test of time.

Without precision and exactingness in handiwork, the joinery quality dwindles, as does the overall quality of the finished product.

As we’ve discussed, flame cutting and precision are almost synonyms. They’re one and the same (when performed by an expert specialist with optimal equipment.) The work, including its impact joinery and connections, upholds the standards, delivering products that look good and have reliable, foundational bones that will never fail.

You’ll encounter flame cutting fabrication professionals throughout Southwestern Ontario. Some of them are excellent at what they do – in fact, most of them are. It’s an industry that attracts skilled people with attention to detail.

So, what separates Amber Steel from the pack? What do you get from us when you invest in our flame cutting fabrication services that you wouldn’t get from a company offering similar services?

Yes, we continually invest in cutting-edge technology and tools for the best results. Yes, we apply the correct approach to the appropriate product. Yes, our workforce is dedicated and passionate about what they do.

These are all highly desirable characteristics – but they’re not the entirety of our differentiating factors.

Instead, combining these traits with our commitment to customer satisfaction sets us apart.

When you partner with Amber Steel, you’re getting someone on your side who wants what’s best for you. When you thrive, we thrive. Our desire to fabricate steels that drive business growth for you makes us stand out from our competitors.

Amber finds every possible angle to give you an advantage when you work with us. It’s not about cashing a cheque. It’s about delivering the appropriate, most profitable solutions for your business’s needs.

As much as steel fabrication impacts the bedrock of our society, our expertise and passion can be the bedrock for your business success.

Want to learn more about how our flame cutting fabrication services can make a big-picture impact on your company? Reach out to us today with your inquiries.

We look forward to learning about your business, its strategies, and its needs surrounding flame cutting structural steel.