We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

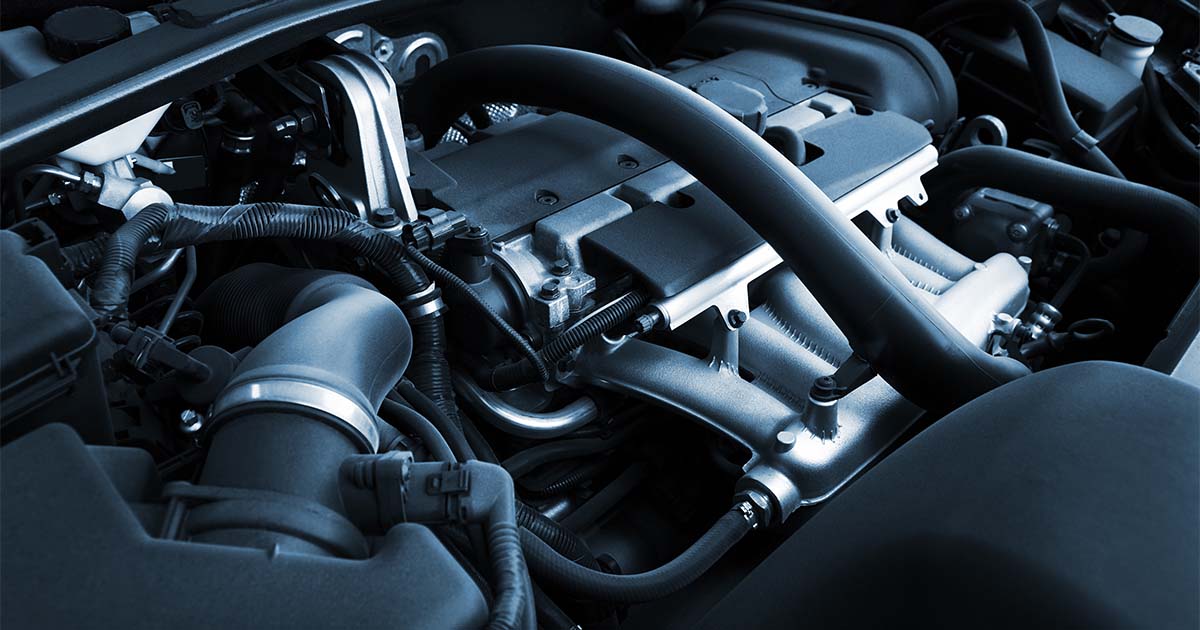

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

Competition is rampant in automotive manufacturing unless you’re one of Canada's four heavyweights in the sector. Even the massive players must do everything possible to stay ahead of the game, as there’s a constant struggle for supremacy.

You’ve always got to be looking for a competitive edge in the automotive world.

Sometimes, marketing, sales, or other abstract business growth strategies make the difference. Most of the time, however, lasting success comes down to the nitty-gritty of assembly processes.

In other words, are your manufacturing approaches, techniques, and technologies more efficient than your competition?

Laser cutting is a prominent example of technology giving automotive manufacturing businesses a competitive edge. It’s revolutionized the sector due to its vast benefits, leading to its widespread implementation.

In this post, we’ll break down the applications and benefits of laser cutting in the auto manufacturing sector.

Aside from having numerous flexible applications (e.g., fabricating metal components, cutting plastic parts, and branding-related engraving/marking), laser cutting can integrate with robotic systems. The streamlined results have yielded a more cost-effective and functionally efficient sector.

As your “total source” service for producing high-quality steel products, we apply the most suitable techniques to each project. We invest in cutting-edge technology and equipment to ensure there’s always a solution for our clients, whether straightforward or alternative, helping them achieve all specifications and tolerances.

Contact us today if you’re mulling over a project in your mind or wish to learn more about steel cutting.

CO₂ and fibre lasers are the two most regularly featured in the automotive manufacturing industry, offering the desired balance of accuracy, speed, and budget-friendliness.

Typically, CO₂ lasers cut non-metallic materials (i.e., plastic, fabrics, and rubber). Their versatility lends itself to the precise cutting of intricate patterns and shapes. These lasers fit seamlessly into high-volume production scenarios because they’re efficient, fast, and accurate. They’re also low maintenance, speaking further to their ability to streamline production.

The material being cut, precision/accuracy-based needs, and production volume all impact your choice of laser cutter. Consistency, reliability, and speed are all necessary to meet the demands of this fast-moving, competitive sector.

Here’s a list of car parts that often undergo laser cutting during manufacturing:

Doors.

Dashboards.

Bumpers.

Interior panels.

Car seats.

Engine components.

Below, we’ll delve further into laser cutting’s role in automotive manufacturing and how it streamlines the processes throughout the industry.

Laser cutting is implemented to cut the following plastic parts:

Interior panels and dashboards.

License plates.

Bumpers.

Pillars.

Light housings.

Trims.

Spoilers.

Etc.

Automotive components are constructed with a diverse array of plastics, such as acrylic, HDPE, ABS, polycarbonate, TPO, and polypropylene.

Whether plain or painted, plastics can be integrated with carbon/glass-fibre-reinforced support systems, fabric-covered interior pillars, and other such materials.

The injection moulding process yields extra plastic residue, which laser cutting can trim. Furthermore, lasers can drill or cut holes for parking sensor lights, switches, fixing points, and other components.

Textiles like upholstery fabrics are a frequent fixture of a car’s interior. The fabric type and thickness will dictate the processing speed for manufacturing these materials.

Precision cuts are used for most synthetic textiles, and the edges are sealed, offsetting any fraying when seats are assembled and stitched.

Accurate Airbag and Seatbelt Sealing and Cutting

Conventional cutting methods are prone to wear and tear when used for airbag sealing.

Conversely, laser cutting seals airbags while reducing the likelihood of wear.

Before being stitched together, flat-woven airbag materials are shaped with a laser cutter. They’re also silicone-coated for optimal permeability.

A laser cutter is also best suited to one-piece-woven (OPW) airbags because they require trimming.

In these scenarios, there’s no contact and fabric handling is limited, preventing damage that could hamper the structural integrity of an airbag.

Metal parts such as hoods, body panels, doors, and fenders often undergo laser cutting. As are gears, shafts, bearings, and other engine components.

Laser cutting is also used when manufacturing suspension components and exhaust systems.

The automotive industry's ongoing shift towards lighter, stronger materials for better fuel efficiency and performance has made laser cutting even more critical. Materials such as high-strength steel, aluminum alloys, and composites require the precise and delicate handling that laser cutting offers.

This technology is particularly adept at cutting complex shapes and small, precise features in these advanced materials, which are often challenging to process using traditional methods.

Laser cutting minimizes the risk of material deformation or damage, often a concern with conventional cutting methods, particularly when working with delicate or thin metals. The contactless nature of laser cutting means there's less mechanical stress on the material, resulting in cleaner edges and a higher-quality finish.

With that said, laser cutting is not always the best way to cut metal automotive parts:

When it comes to thick metal sheets, plasma cutting is more effective and faster. This is the case for certain structural components of a vehicle’s frame, suspension, and exhaust system.

For very thick steel plates, like heavy-duty chassis components for commercial vehicles, construction equipment, or heavy trucks, flame cutting is the way to go.

Commonly, leather (synthetic or authentic) is cut with lasers because of how fine-tuned the process and machinery are.

This section will focus on the benefits of laser cutting in automotive manufacturing.

The computer numerical controls (CNC) in laser cutters enable them to cut precisely preprogrammed outlines.

Automotive manufacturing companies continually rely on laser cutting as its features (like CNC) streamline production with consistent, never-changing parts, reducing the time needed to complete work.

Glass, rubber, fabrics, and plastics all have their place in automotive manufacturing and can all be cut with lasers.

Laser-cut components and materials exist in almost every car’s exterior and interior. More to the point, laser cutting is implemented throughout automotive manufacturing, from earlier designs to development and assembly.

Using a high-density heat source, laser cutters produce clean and precise results.

Also, laser cutters produce a light wave with a wavelength of 10,000 nm. The metal’s partial energy absorption makes precision cutting a reality since it yields a molecular structure change in the metal.

Beam quality is assessed with the beam parameter product (BPP). For example, CO₂ lasers have an 8-9mm BPP. This combines with intensely concentrated heat, yielding near flawless cuts, explaining the widespread usage throughout automotive manufacturing.

Often, laser cutters find themselves a crucial component of airbag sealing and cutting, producing error-free results, which is why they’re sought-after throughout the sector.

Here, we’ll introduce the concept of output-to-space efficiency and how optimizing it benefits automotive manufacturers.

Compared to its throughput, laser cutters are compact, even relatively small. Thus, they can be seamlessly integrated into a manufacturing setting, not taking up much space. As such, they’ll fit into smaller shops as much as larger spaces, maintaining the utmost precision and highest quality.

Every stage of automotive manufacturing—from the design phase until assembly—benefits from laser cutters due to such machines' accuracy, speed, and precision.

Integration capabilities with robot systems (because of the 3D nature of some items) make lasers even more of a streamlining tool.

Some robots can pick up parts, offer them to a processing head, and maneuver them to complete the cut.

A laser can also be installed on a robot arm, enabling the beam to move around a part’s 3D contours.

Wide ranges of processes can be implemented when the above techniques are combined. Workpieces and laser heads are managed and streamlined to execute cutting operations optimally.

Several laser processes can be completed within one robot cell, improving production and cycle times. Processing quality, repeatability, and dependability are all enhanced, lowering rejection rates and reducing expensive material waste. Thus, laser cutters serve large-batch and small-scale productions alike.

Are you an automotive parts manufacturer seeking speed, precision, accuracy, dependability, and adaptability?

Laser cutting can make all the difference in the world to your enterprise. It’s already an integral component of automotive manufacturing because of the streamlining qualities discussed above.

Regardless of the components that laser cutting can help manufacture, it’ll generate top-tier results and products on which your company can rest their reputation.

This versatile form of steel-cutting fits into almost all manufacturing environments, including small shops. Yet, it entirely fits into larger-scale settings. It’s compact, seamless, and can integrate with robotic systems to further streamline production.

Amber Steel specializes in plasma, flame, and laser cutting, offering your enterprise a “total source” solution to produce top-tier steel products, including automotive manufacturing parts. We’re committed to investing in cutting-edge technology and equipment to ensure our clients have alternatives to achieve bespoke specifications and tolerances.

Learn more about steel cutting by contacting us today. Or, reach out with an email or phone call if you have a project in mind and wish to discuss it with industry experts.

In today's dynamic world of automotive manufacturing, precision and performance have become paramount considerations in every aspect of the production process. One cutting-edge technology that has significantly contributed to meeting these demands is plasma cutting.

The introduction of plasma cutting has revolutionized the way automotive components are fabricated. At its core, plasma cutting involves utilizing a high-velocity jet of ionized gas, or plasma, to melt through various types of metals with unparalleled accuracy. This technology has rapidly gained traction within the automotive sector due to its ability to deliver intricate cuts with exceptional precision. From chassis components to intricate engine parts, plasma cutting has proven to be a versatile solution that addresses the stringent demands of modern automotive design and manufacturing.

The automotive industry operates in an environment where even the slightest deviation from precision can have cascading effects on overall performance.

Whether it's ensuring a seamless fit between parts, optimizing aerodynamics for fuel efficiency, or enhancing safety through well-constructed components, precision stands as the cornerstone of automotive manufacturing.

Additionally, the industry's competitive landscape compels manufacturers to not only deliver reliable and high-performing vehicles but also to do so efficiently and cost-effectively. This is where the concept of performance comes into play—each component must contribute to the vehicle's overall performance while being produced within strict time frames.

In this blog post, we will focus on the mechanics of plasma cutting and explore how it addresses the precision and performance challenges in automotive manufacturing. By the end, it will be clear how plasma cutting has become an indispensable tool in the automotive industry's pursuit of precision and performance excellence.

In the realm of modern manufacturing, where intricate designs and precise cuts are paramount, plasma cutting emerges as a cutting-edge technique that has transformed the landscape of metal fabrication.

Plasma cutting is a thermal cutting process that relies on a high-velocity stream of electrically ionized gas, known as plasma, to effectively cut through a wide range of conductive materials, including steel, aluminum, and stainless steel. This method offers a level of precision and versatility that is hard to match with conventional cutting techniques.

By combining electrical energy and compressed gas, plasma cutters create a controlled arc that heats the material to its melting point and blows away the molten metal, resulting in a clean and accurate cut.

Plasma cutting technology operates on the principles of electrical conductivity, gas dynamics, and heat transfer. The process begins with an electrical arc being generated between an electrode and the workpiece, ionizing the gas and transforming it into plasma. The plasma's extreme heat—reaching temperatures in excess of 30,000 degrees Fahrenheit—rapidly melts the metal it comes into contact with. Simultaneously, a high-velocity jet of gas (often nitrogen or oxygen) blows away the molten metal, effectively severing the material along the desired cutting path. The precision of the cut is determined by the CNC (Computer Numerical Control) system that guides the movement of the cutting torch, ensuring intricate and accurate shapes can be achieved with exceptional repeatability.

Precision and Intricacy: Plasma cutting's ability to create intricate cuts with minimal distortion is unmatched, making it a preferred choice for crafting complex automotive parts that demand exact specifications.

Versatility: Unlike laser cutting, which may struggle with certain materials, plasma cutting can effectively handle a wide range of conductive materials, including thicker metals.

Cost-Effectiveness: Plasma cutting tends to be more cost-effective than laser cutting for thicker materials, making it an economical choice for various automotive components.

Speed: Plasma cutting's high cutting speeds contribute to quicker production cycles, facilitating efficient automotive manufacturing.

Reduced Heat-Affected Zone: Compared to traditional cutting methods, plasma cutting generates a smaller heat-affected zone, minimizing material warping and enhancing precision.

Enhanced Material Utilization: The precision of plasma cutting minimizes waste, optimizing material utilization and reducing production costs.

Precision stands as the foundational pillar in the intricate realm of automotive manufacturing, dictating the success of every facet of part fabrication.

The interwoven puzzle of vehicle components necessitates meticulous accuracy, where even the smallest screw to the most complex engine part must seamlessly fit. Deviations from precision can lead to issues like compromised safety and subpar performance, deemed unacceptable in the automotive landscape.

The impact of precision extends beyond immediate results, influencing long-term reliability and customer satisfaction. A precisely cut engine component ensures optimal combustion efficiency, while accurately fitted body panels enhance aerodynamics and aesthetics.

However, achieving this precision is a multifaceted challenge due to factors like material properties and design intricacy.

Vehicles represent intricate engineering marvels, where a symphony of components harmoniously collaborates to deliver outstanding performance, safety, and efficiency.

A detailed exploration of automotive components' performance demands highlights their critical role in ensuring reliability and functionality. From engine parts enduring extreme conditions to chassis components ensuring stability, every element contributes to a seamless driving experience. Precision and structural integrity directly influence overall performance, longevity, and safety ratings.

The imperative for high-quality cuts goes beyond aesthetics—it's intrinsic to performance. Irregular cuts or misalignments can trigger stress concentrations, undermining structural integrity and efficiency. Each cut must seamlessly align with the design intent to ensure components interact without fault, emphasizing the pivotal role of precision.

Plasma cutting technology emerges as a robust ally in meeting stringent performance requirements. Its precision ensures complex components are manufactured consistently and accurately. Swift cutting speeds maintain production efficiency without compromising quality. Moreover, plasma cutting's minimal heat-affected zone and reduced material distortion safeguard structural integrity, producing components capable of withstanding automotive challenges.

In the ever-evolving landscape of automotive manufacturing, precision and performance are complemented by the innovative capabilities of plasma cutting technology.

Plasma cutting excels at maximizing material utilization by virtue of its precise and controlled cuts. This efficiency is a result of the technology's ability to create intricate shapes with minimal waste. This is particularly advantageous in automotive manufacturing, where raw material costs can be substantial. With plasma cutting, manufacturers can optimize material usage, reducing costs and minimizing environmental impact.

The fast-paced nature of the automotive industry demands manufacturing processes that can keep up with high production volumes. Plasma cutting's rapid cutting speeds make it a compelling solution for automotive manufacturing. By swiftly and accurately cutting through materials, plasma cutting significantly reduces production cycle times. This efficiency translates into higher output rates and shorter lead times, allowing manufacturers to meet market demands more effectively.

Automotive design has evolved beyond traditional shapes, necessitating the ability to fabricate intricate and unconventional components. Plasma cutting's precision and versatility cater to these demands, enabling manufacturers to execute complex designs with ease. This flexibility extends to various material thicknesses, making it possible to produce both delicate and robust components while adhering to strict design tolerances.

The heat generated during cutting processes can adversely affect material properties, leading to warping, distortion, and decreased mechanical strength. Plasma cutting, with its localized heat application and high cutting speeds, minimizes the size of the heat-affected zone. This characteristic preserves the material's structural integrity, crucial for ensuring the long-term performance and reliability of automotive parts.

Traditional cutting methods often necessitate extensive post-processing steps, such as deburring, grinding, or machining, to achieve the desired finish and precision. Plasma cutting's high precision reduces the need for such labour-intensive post-processing. This not only saves time but also streamlines the production process, resulting in components that require minimal finishing touches before assembly.

The automotive industry's demand for precision has driven continuous advancements in plasma cutting technology. Innovations in power sources, torch design, and CNC systems have collectively enhanced the precision, speed, and versatility of plasma cutting processes. Modern plasma cutting systems offer greater automation, enabling manufacturers to execute intricate cuts with exceptional accuracy. These advancements have made plasma cutting a reliable solution for fabricating intricate automotive parts that demand uncompromising precision.

CNC plasma cutting technology takes the precision of plasma cutting to a whole new level. Computer Numerical Control (CNC) systems drive the movement of the cutting torch based on digital design data, ensuring that each cut is executed with unparalleled accuracy. This level of precision is especially critical in automotive fabrication, where components must fit seamlessly and adhere to strict tolerances. CNC plasma cutting allows for the reproduction of complex designs across multiple parts, guaranteeing consistency and quality.

Chassis Components: The intricate shapes and contours of chassis components require precision cutting to ensure proper alignment and structural integrity.

Exhaust Systems: Plasma cutting is instrumental in crafting exhaust components with precise angles and curves, optimizing flow dynamics and contributing to engine performance.

Body Panels: Automotive aesthetics and aerodynamics demand accurate cuts in body panels. Plasma cutting enables the creation of custom shapes that contribute to vehicle design and efficiency.

Engine Parts: Engine components, such as cylinder heads and intake manifolds, benefit from plasma cutting's ability to create intricate passages and chambers with precision, enhancing combustion efficiency.

At Amber Steel, we specialize in laser, plasma and flame cutting, and have always been a "total source" service for the production of quality steel products. Quality is achieved by utilizing the right production technique for the right product. Our continual investment in equipment and technology enables us to offer clients many production alternatives to achieve exact product specifications and tolerances. If you’re interested in learning more about steel cutting or have a project in mind that you would need our expertise on, do not hesitate to reach out. We’re always one email or phone call away.