We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

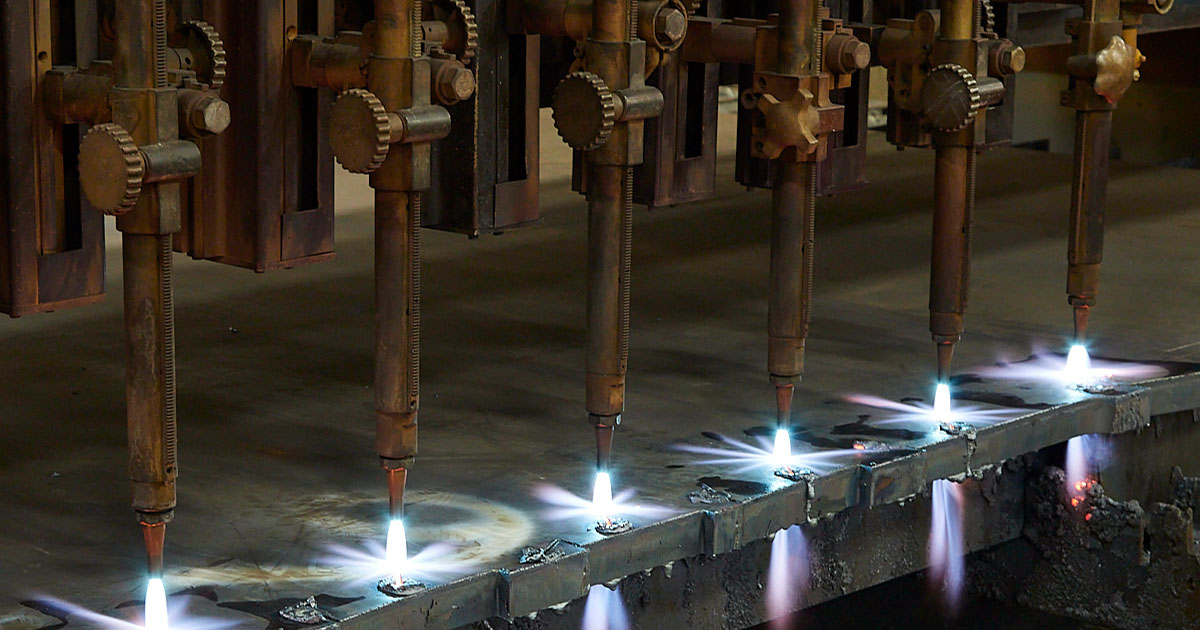

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

All industrial projects have one thing in common: they necessitate a significant financial investment.

Even if, hypothetically, the upfront costs of shipbuilding or construction ventures (for example) are relatively frugal compared to industry standards, the dollar amounts involved would still be nothing to scoff at.

For instance, the cost range to build an industrial facility can jump to $180 per square foot and beyond, depending on complexity.

Modern cruise ships cost up to $900 million on average to build. On the lower end, it’s $500 million.

These investments can seem daunting, even when you’ve made financially savvy decisions. However, these projects often yield returns far exceeding those upfront costs — provided both strategy and execution are sound.

Part of sound strategy and execution is ensuring all facets of these projects optimize mechanical and financial efficiency.

On the above note, metal fabrication and steel cutting are crucial in heavy industrial projects, from shipbuilding and construction to precision engineering and aerospace. It’s a foundational component ensuring robust stability and reliability — responsible for providing the bones of all structures.

This brings us to flame cutting, which is aimed at the most robust industrial metals and materials.

With flame cutting, mechanical efficiency is at the forefront, requiring only one pass to slice through 270mm-thick steel. There’s also the benefit of cost-effectiveness. Its economic implementation of gas and oxygen makes it ideal for many projects.

There’s a caveat with flame cutting, though — that being quality control.

Not all flame-cutting services are created equal, and the margin for error in heavy industrial applications is virtually non-existent. You can’t afford low-quality work on your projects.

At Amber Steel, our flame-cutting services are second to none. Our expert technicians have mastered their craft, and our technology is state-of-the-art.

These benefits combine to ensure the work is completed efficiently, cost-effectively, and of the highest quality. We employ a consultative approach centered around your needs as a client, tailoring our steel fabrication solution to what will most benefit your project and budget.

We’ll open this section with a disclaimer: flame cutting has specific applications and limitations, typically beginning and ending with thick, heavy-duty metals.

Using flame cutting for thin metals in situations calling for high levels of precision won’t generate the desired results.

Thus, the prerequisite for quality control is ensuring flame cutting suits your project.

When you apply flame cutting in the incorrect scenario, all the other quality control measures in the world mean nothing because the work is doomed to disappointment. The method and technicians involved aren’t being set up for success.

Below, we’ll discuss the factors in choosing the correct cutting method, your first step in ensuring quality control.

Thin metals are not suited to flame-cutting — waterjet and hand-cutting methods are more suited to such projects.

Conversely, the robustness of flame cutting is far more suited to thicker metals (although, depending on other factors, you might be better off choosing plasma cutting).

Aluminum is a softer metal, typically better suited to abrasive methods and hand tools. Alternatively, low alloy steels, cast irons, and carbon steel respond best to flame cutting.

Weigh your metal type's hardness, thickness, and conductivity before determining the best flame-cutting method for your project.

In many aerospace applications, minimal distortion and high accuracy are paramount — in which case, flame cutting won’t fit.

Construction work offers more wiggle room with accuracy-based needs. You don’t need to be ultra-precise, often making flame cutting the ideal choice for these projects (in no small part due to its cost efficiency).

Some metals demand a high-cost cutting solution — otherwise, the job won’t be done correctly.

However, many projects involve materials suited to more cost-effective and budget-friendly solutions like flame cutting.

Overspending on a steel-cutting solution might yield an excellent final product but in a financially damaging fashion. Quality control is rendered useless if you’re getting raked over the coals because you’ve invested in a service that devours your budget when you could’ve chosen something more affordable that would’ve delivered equal results.

Manual and laser cutting are more suited to low-volume custom work.

However, robust high-volume jobs with thick steels—calling for fast turnaround times — will benefit from the speed and efficiency of flame cutting.

These factors can all be complicated to weigh on your own. So, consult with an industry expert who fully grasps your project's scope, materials, and spending limitations before deciding whether flame cutting fits your project.

If flame cutting is the ideal choice, the rest of the quality control measures we discuss will come into play.

Here are the pivotal benefits of choosing flame-cutting services for your project:

These are significant benefits that can bolster a given project. Yet, everyone can fly out the window without the appropriate quality control measures.

Quality control must be one of the top priorities of your flame-cutting service provider.

When your steel-cutting partner is rigorous about ensuring the utmost quality, they maximize the benefits and neutralize potential pitfalls.

Safety is crucial for the types of construction projects calling for flame-cutting services.

First and foremost is the human element of keeping workers safe. You don’t want anybody’s well-being at risk on a job site.

There are also legal and financial ramifications when someone gets hurt, damaging your reputation and bottom line.

On the above notes, flame-cutting machines possess high-temperature flames and involve combustible gases. Protective gear, adequate ventilation, and safety protocol adherence are vital.

When these factors aren’t managed properly, it puts workers at risk. Safety flies out the window.

Furthermore, flame-cutting service providers who don’t prioritize safety are telling you a lot about the rest of their quality control practices. The well-being of labourers and technicians doesn’t matter to such a company. Then, they probably don’t care too much about the quality of their final product, either.

The value of quality control can’t be overstated as it pertains to flame cutting.

Investing in a flame-cutting service with rigorous quality control measures ensures optimal value for dollars spent and a top-notch final product.

Still, it’s worth asking: What are the parameters of “quality” in relation to flame cutting? We’ll answer in the bullet points below:

These are critical factors in ensuring high-quality results from your flame-cutting service provider. Industry leaders will stop at nothing to ensure you get nothing but the best. They’ll be rigorous about quality control measures to ensure each cut follows the parameters detailed above.

Investing in a partnership with a steel-cutting service provider is a significant decision for your project.

Your choice of who to work with will depend on your vetting through prospective service providers and third parties, determining who best fits your needs.

Due diligence will be your guide. This means looking up online reviews, requesting references and portfolios of work from prospective partners, and seeking testimonials.

Time might be of the essence to get your project underway, but your choice in flame-cutter shouldn’t be rushed.

Find out how prospective partners will ensure quality. Investigate if they’re committed to offering you the most value and providing the best results for your project or merely trying to sell you something.

At Amber Steel, our clients and the needs of their projects come first.

Speak with us as a prospect, and we’ll provide expertise and insights that inform you of the quality of our work and the best ways to proceed with what you’re doing.

Contact us today If you’re seeking flame, plasma, or laser-cutting services and wish to consult with one of the industry’s foremost leaders.

Flame cutting is the go-to method for slicing through thick steel, making it a valuable tool for all kinds of industrial settings.

It's where precision meets efficiency, especially when it comes to heavy-duty applications. At Amber Steel, we pride ourselves on our years of expertise with cutting-edge flame cutting techniques to tackle even the most formidable projects with skill and precision.

In this post, we’ll zero in on the challenges of and best practices for flame cutting thick steel. Whether it's the colossal ships, structural steel for construction, or robust oil and gas machinery, mastering these challenges is key to achieving high-quality flame cutting results.

Let's cut to the chase and explore how every flame cutting challenge is an opportunity to innovate.

At Amber Steel, we specialize in laser, plasma and flame cutting, and have always been a "total source" service for the production of quality steel products. Quality is achieved by utilizing the right production technique for the right product. Our continual investment in equipment and technology enables us to offer clients many production alternatives to achieve exact product specifications and tolerances. If you’re interested in learning more about steel cutting or have a project in mind that you would need our expertise on, do not hesitate to reach out. We’re always one email or phone call away.

Why do the heavy hitters of industry — think shipbuilders, mining machinery manufacturers, and bridge engineers — often turn to flame cutting?

The answer lies in its unique blend of technical advantages tailor-made for handling the heavyweight contenders of the steel world.

Precision: When it comes to thick steel, flame cutting allows for precise cuts in steel plates that can be several inches thick, a feat not all cutting methods can claim with the same level of finesse.

Cost-Effectiveness: Flame cutting scores high on cost-efficiency, especially for thick materials where alternative methods might cost a fortune in comparison.

Versatility: Whether it's a straight line or a complex contour, it handles diverse shapes with ease. This adaptability makes it a go-to solution for everything from the backbone of skyscrapers to the hulls of ships.

Simplicity: While "simple" might not be the first word that comes to mind when you think about cutting through several-inch-thick steel plates, flame cutting offers a straightforwardness that's hard to beat. It’s reliable, uncomplicated and accessible.

Imagine trying to perfectly toast a marshmallow over a campfire, aiming for that golden brown without turning it into a charred lump.

That's a bit like the careful balance required in flame cutting, where the goal is to melt and cut steel with surgical precision without turning the surrounding areas into a metallurgical mess.

The challenge here is not just to cut, but to cut without compromising the integrity of the steel beyond the cut line. Flame cutting heats steel to its melting point, around 1,370°C to 1,540°C (2,500°F to 2,800°F). This intense heat needs to be controlled with extreme precision.

Thermal distortion is what happens when the heat from cutting decides to go on a little tour into the surrounding metal, causing it to warp or distort. In thick steel, this is even more pronounced due to the sheer volume of metal and heat involved.

Another concern is the Heat-Affected Zone (HAZ), which is the area around the cut where the steel hasn't melted but has still felt the heat. This area can undergo changes in microstructure, affecting the steel's mechanical properties.

Heat management in flame cutting for thick steel is an artful balance of science, technology, and human skill.

Preheating: By warming the steel before cutting it, we reduce the risk of thermal shock and distortion, making the cutting process smoother and the results more predictable.

Utilizing Technology: CNC (Computer Numerical Control) systems offer precise control over the process, while the expertise of seasoned operators ensures adjustments are made in real-time.

Controlled Cutting Speed: The cutting speed must be carefully managed to balance efficiency with precision, avoiding excessive heat buildup.

Post-Cut Cooling Practices: After the cut, controlling how the steel cools down is crucial. Techniques like covering the cut parts with insulating blankets or using controlled environment cooling help minimize stresses and distortion.

Controlling the heat ensures that the final product is cut to size while retaining its structural integrity and strength, ready for whatever comes next.

The thickness of the steel dictates everything from the heat required to the speed of the cut, which impacts both efficiency and quality.

Thicker steel requires more heat to be cut through, which can slow down the process and increase the heat-affected zone (HAZ). Thicker materials also present challenges like increased dross (residual material left from the cutting process), rougher cut surfaces, and wider kerf width (the width of the material removed during cutting).

On the flip side, thinner materials heat up and cool down quicker, allowing for faster cuts but also raising the risk of warping due to rapid temperature changes.

It takes a comprehensive approach that combines technology, experience, and careful planning to overcome the challenges posed by material thickness in flame cutting.

Preheating: Just as with managing heat, preheating the steel can help minimize thermal gradients and reduce the risk of thermal stress and distortion, particularly in thicker materials. This makes the cutting process more uniform and predictable.

Optimized Cutting Parameters: Adjusting cutting parameters such as flame intensity, cutting speed, and oxygen pressure for different material thicknesses is essential. Experience, along with guidelines from equipment manufacturers, is key in finding the optimal settings for each job.

Multiple Pass Cutting: For exceptionally thick materials, using multiple passes can be an effective way to manage heat input and improve cut quality. The first pass preheats and begins the cut, with subsequent passes deepening the cut until completion.

Utilizing Technology: Advanced CNC systems provide precise control over the cutting process, allowing for adjustments in real-time to accommodate materials of varying thicknesses. This technological edge ensures consistent quality and efficiency across different projects.

Managing these variables meticulously ensures that each piece of steel meets the correct dimensions and high standards expected of industrial products.

Selecting the right gas mixture plays a significant role in efficiency, quality, and cost-effectiveness of the cutting process, especially when dealing with thick steel.

First, the gas mixture directly impacts the flame's temperature, which in turn affects how efficiently and cleanly the steel can be cut. Higher flame temperatures allow for quicker cuts but require careful management to avoid compromising cut quality.

Additionally, certain gases enhance the steel's oxidation process during cutting. This allows for a faster, cleaner cut by helping to expel the molten metal more effectively.

Finally, every gas comes with its own set of safety and cost implications. Factors like flammability, health hazards, and price per cubic foot must be balanced against the gas's cutting performance to make an informed choice.

Oxygen: Pure oxygen is used to increase the flame temperature and facilitate the cutting process.

Acetylene: Known for its high flame temperature and efficiency in cutting thick steel, acetylene is often chosen for jobs requiring precision and speed. However, it's more expensive than other gases and has a narrower range of safe operating conditions.

Propane and Propylene: These gases offer a balance between performance and cost. They have lower flame temperatures than acetylene but are safer to handle and more economical, making them suitable for cutting thicker steel sections where the highest cutting speed is not the primary concern.

Natural Gas: Natural gas is an economical option for flame cutting operations, although its performance is lower than acetylene or propylene. Its availability and cost can make it an attractive choice for large-scale or less precision-critical cutting tasks.

Choosing the right gas mixture for each project ensures both the efficiency and quality of the cutting process, as well as the overall success of the fabrication process that follows.

Application-Specific Selection: The best approach to gas selection involves considering the specific requirements of the job, such as material thickness, desired cut quality, and budget constraints.

Combining Gases: Sometimes, a combination of gases can be used to optimize performance, taking advantage of the beneficial properties of each gas.

Trial and Error: Experimenting with different gas mixtures can help identify the best option for balancing cut quality, speed, and cost for specific applications.

Flame cutting, with its unique challenges and technical demands, is not just about having the right tools — it's about having the right partner.

At Amber Steel, our commitment to quality, precision, and customer satisfaction is at the core of everything we do. We understand that the success of your projects depends on the accuracy and quality of the cutting process. That's why we've honed our skills, invested in the latest technology, and cultivated a team of experts who are passionate about delivering excellence.

Choosing Amber Steel as your flame cutting partner means entrusting your projects to a team that views your success as their own. We take pride in our ability to meet the specific needs of each client, whether it's adjusting based on material thickness, mastering heat management, or choosing the correct gas mixture.

Your projects demand precision, quality, and a commitment to excellence. At Amber Steel, we're ready to deliver on those demands, ensuring that every cut is a step toward the successful completion of your project. Contact us today to learn more about how we can support your flame cutting needs and help bring your vision to reality.